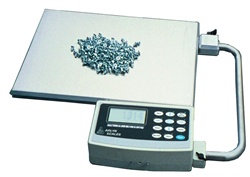

How many rivets are in the bucket? How many envelopes are ready to be mailed? What is an easy way to fill packages of connectors with exactly 10,000 pieces? How many injection molded parts were fabricated during the first shift? These are all questions that can be answered by parts counting scales. An accurate industrial scale will obtain the precise weight of a full container of parts that is placed on its platform. If the weight of the empty container is known, and the weight of an individual part is also known, then the number of pieces in the container can be calculated. The first step is to take the measured weight and subtract the empty weight of the container. This leaves just the total weight of all of the parts. Now, the weight of a single part can be divided into this total. The result will be the total number of parts. The most important part of this procedure is to determine the weight of a single part with great accuracy. Generally, the capacity of the parts counting scale will be specified by the maximum weight of a full container. Using one of our initial examples, a connector manufacturer may need to fill their packages with 10,000 very expensive connectors. If each connector weighs exactly .008734 lb, then 10,000 pieces will weigh 87.34 lb. If the container weights 8.40 lb, then the total, filled container will weigh 95.74 lb. An excellent quality electronic scale may be able to accurately weight this container to within .01 lb. That means that the total count should be accurate to within one or two pieces. But it would not be advisable to use the same parts counting scale to initially obtain the weight of one individual part. With one part on the platform, the scale would register a weight of .01 lb instead of .008734, leading to a very large counting error that could be as high as 20%. One method that can be used to obtain a better part weight is to count out ten of these connectors and try to weigh them. Now, the scale will register a weight of .09 lb, instead of .08734. While the error has been reduced to only 2 or 3%, it is still much too high. Of course we could not count out 100 parts by hand to reduce the error still further, but this becomes time consuming and cumbersome. A more effective method would be to use a scale with a much higher sensitivity for piece weight determination, even if the total capacity was much too low for the total package. For example, a scale with a 1 lb capacity may have a readability of .0001 lb. Now, a sample of 10 connectors would yield a weight of .0873 lb, resulting in an error of less than 1/10 of 1%. While it is possible to manually enter the container tare weight and the individual piece weight into the parts counting scale, it is much better if the scale has the ability to store this data for future use. This can allow a wide variety of different parts to be carefully weighed on the low capacity scale, with their piece weights stored on the larger capacity scale. Similarly, the empty weights of different sized containers can also be stored. Parts counting scales offered by Arlyn Scales provides the user with as many as 500 memory locations for storing this data. The part number or name is stored with the piece weight, making it easy to retrieve this information when counting that part. For even easier use, these piece weights and names may be downloaded from a database stored on a computer. An even better solution to using a second scale to determine the piece weight would be to choose a scale that had both a high capacity and an excellent readability. An example of this type of parts counting scale is the Arlyn Scales Ultra Precision SAW scale. For our example described above, the 100 lb capacity scale has a readability of up to 0.0005 lb. This provides very good parts counting accuracy. These scales also include memory to store the piece weight and container tare weight. This combination results in an electronic scale that is both accurate and easy to use.

How many rivets are in the bucket? How many envelopes are ready to be mailed? What is an easy way to fill packages of connectors with exactly 10,000 pieces? How many injection molded parts were fabricated during the first shift? These are all questions that can be answered by parts counting scales. An accurate industrial scale will obtain the precise weight of a full container of parts that is placed on its platform. If the weight of the empty container is known, and the weight of an individual part is also known, then the number of pieces in the container can be calculated. The first step is to take the measured weight and subtract the empty weight of the container. This leaves just the total weight of all of the parts. Now, the weight of a single part can be divided into this total. The result will be the total number of parts. The most important part of this procedure is to determine the weight of a single part with great accuracy. Generally, the capacity of the parts counting scale will be specified by the maximum weight of a full container. Using one of our initial examples, a connector manufacturer may need to fill their packages with 10,000 very expensive connectors. If each connector weighs exactly .008734 lb, then 10,000 pieces will weigh 87.34 lb. If the container weights 8.40 lb, then the total, filled container will weigh 95.74 lb. An excellent quality electronic scale may be able to accurately weight this container to within .01 lb. That means that the total count should be accurate to within one or two pieces. But it would not be advisable to use the same parts counting scale to initially obtain the weight of one individual part. With one part on the platform, the scale would register a weight of .01 lb instead of .008734, leading to a very large counting error that could be as high as 20%. One method that can be used to obtain a better part weight is to count out ten of these connectors and try to weigh them. Now, the scale will register a weight of .09 lb, instead of .08734. While the error has been reduced to only 2 or 3%, it is still much too high. Of course we could not count out 100 parts by hand to reduce the error still further, but this becomes time consuming and cumbersome. A more effective method would be to use a scale with a much higher sensitivity for piece weight determination, even if the total capacity was much too low for the total package. For example, a scale with a 1 lb capacity may have a readability of .0001 lb. Now, a sample of 10 connectors would yield a weight of .0873 lb, resulting in an error of less than 1/10 of 1%. While it is possible to manually enter the container tare weight and the individual piece weight into the parts counting scale, it is much better if the scale has the ability to store this data for future use. This can allow a wide variety of different parts to be carefully weighed on the low capacity scale, with their piece weights stored on the larger capacity scale. Similarly, the empty weights of different sized containers can also be stored. Parts counting scales offered by Arlyn Scales provides the user with as many as 500 memory locations for storing this data. The part number or name is stored with the piece weight, making it easy to retrieve this information when counting that part. For even easier use, these piece weights and names may be downloaded from a database stored on a computer. An even better solution to using a second scale to determine the piece weight would be to choose a scale that had both a high capacity and an excellent readability. An example of this type of parts counting scale is the Arlyn Scales Ultra Precision SAW scale. For our example described above, the 100 lb capacity scale has a readability of up to 0.0005 lb. This provides very good parts counting accuracy. These scales also include memory to store the piece weight and container tare weight. This combination results in an electronic scale that is both accurate and easy to use.

-

Web APIHOW TO: Connect to your scale and retrieve weight data using Web API with built-in HTTP REST Methods.

-

MKE-5-ISNOW IN-STOCK: Explosion Proof Intrinsically Safe Weight Indicators. Battery Operated or w/ external power. Click for more.

-

3rd Party IntegrationNEW: Want to add more advanced functions to your existing non-Arlyn scale? Integrate the full featured UpScale Touchscreen Indicator using "3rd-Party Integration" feature.

-

Google SpreadsheetsHOW TO: Data Logging with Google Spreadsheets. Reduce demand on your operators and optimize your data collection process.

-

Keyboard WedgeNEW: Keyboard Wedge Feature. Our Keyboard Wedge Feature transfers data directly from your scale, and into a PC program.

Copyright © 2007-2026 Circuits & Systems Inc. Arlyn Scales. All Rights Reserved. Bigcommerce Development by Optimum7