Arlyn Scales provides scales for all types of clients, including those that work with hazardous materials. For use in volatile areas, Arlyn Scales offers the very best in intrinsically safe and explosion-proof equipment.

What’s So Special About “Intrinsically Safe”?

Many industrial facilities use scales because they need to weigh materials and prepare items for shipping. Electronic scales are most commonly used because they can be read more easily and are generally simple to function, compared to non-electrical scales; however, electricity in the presence of hazardous materials is extremely dangerous.

A typical electronic scale may need to be powered by up to 15 volts or more. And whenever there is electricity, there is a chance that a spark could be created—which in the vicinity of flammable or explosive substances could create a fatal result. So because there is a possibility for damage and danger, any facility that is considered a hazardous environment must stick to the NEC guidelines. But many of them still need to use scales. So what can they do?

Fortunately, Arlyn Scales has addressed the needs of customers that work in hazardous environments and need to use electrical scales. Arlyn Scales manufactures scales for every environment and purpose; however, we offer several scales that are termed “intrinsically safe,” which means they are approved to function specifically in hazardous environments.

A common scale uses electrical power, generally up to 15 volts. This relatively high voltage can create a spark that will ignite the nearby flammable fumes. Clients must have another option for weighing items. Therefore, Arlyn Scales has responded with specialized and intrinsically safe, Explosive Environment Scales.

Explosive Environment Scales

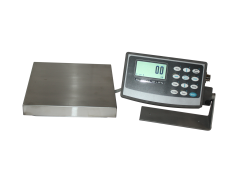

On the surface, a client would not be able to differentiate between an intrinsically safe scale and a basic scale. Arlyn Scales mastered the safe design so that users would still feel comfortable using the specialized weight scale; functions and interfacing with the display are the same. It is the internal construction that is the key difference between the two-scale types. The electronic circuitry within the scale was designed to use very little voltage; each component and wiring length is insulated to retain heat and prevent electrical shorting.

Powering the scale is a C cell rechargeable battery. The lack of an external electrical cable plugged into an outlet prevents another possibility of a surge or short that can cause a harmful ignition. Arlyn Scales understands that a scale is prone to wear and tear over time from placing heavy items on its platform.

In response, designers have created a sturdy holder to prevent any wear and tear to the battery, which can spark and cause a fire if harmed. The holder is built of solid aluminum; any drop or damage aimed at the battery will be impeded by the holder’s strength. An intrinsically safe scale must have a practical design to prevent a battery short from loose leads.

Arlyn Scales constructed the battery holder to stop any power leaving the battery if the leads are shorted; this automatic power impedance prevents internal electrical shorting. The short must be resolved before the battery will emit any more electrical power.

Clients may be concerned with the low level of electricity running through the scale. Will the scale still have the necessary accuracy as a non-intrinsically safe scale? Arlyn Scales has constructed these specialized scales with the same precision of their other scale offerings; internal microcontroller components work well with low voltages, as well as the load cells. The load cells are made from stainless steel, which offers durability for the overall product.

Charging the battery should only be necessary after 24 hours of use. The user will need to remove the battery from the scale to charge in an external charging device within the safe area. It is possible to use a replacement battery in the meantime so that the scale remains operational. Keeping both batteries fully charged will keep the scale working at all times.

But are Intrinsically Safe Floor Scales as Accurate as Basic Scales?

Arlyn Scales has gone to great lengths to ensure customers can have a safe scale in their facility that will evade explosions and fires. But with all of the safety features, many people want to know: if the voltage is less on an intrinsically safe scale, is it as accurate as basic scales?

It’s a valid question, but of course, these scales are just as accurate as basic scales. Yes, they are manufactured differently so that they can operate in hazardous locations. They have internal microcontroller components that work well with low voltages. And the load cells in our intrinsically safe scales are made from stainless steel, which is compatible with low power and makes the scales more durable. Intrinsically safe scales are made differently so that they can operate safely in dangerous locations, but the results they deliver are on the same level as basic scales.

ArlynGuard Scales

Arlyn Scales is uniquely positioned to provide highly specialized equipment for our customers. This is as a US-based factory-direct industrial scales manufacturer and subassembly operation.

We offer ArlynGuard B, C, F, and P Scales that have one or more components that have gone through testing and approval for an impressive range of hazardous locations including:

• Intrinsically safe for use in Class I, II, III; Division I; Groups A through G

• Non-incentive for use in Class I; Division II; Groups A through D

• Suitable for use in Class II; Division II; Groups F & G

• Suitable for use in Class III; Division II

Arlyn Scales takes pride in reliable, sturdy, and safe scales for industrial and laboratory use. It doesn’t matter if the materials that must be weighed are in a freezer, or just might catch fire, Arlyn Scales has served companies from coast to coast. Contact Arlyn Scales today. We look forward to hearing about the details of your industry, and how we can outfit you with the best possible weigh system.